THANKS FOR STOPPING BY OUR TABLE

Hi, I’m Doug! also known as “DreamsVoid”

Seeminly a little famous for biting off more than I can chew. I decided my first true 3D printing project should be to build a printer, as in the RepRap way. Since 2019 with little to no experience with 3D design software, I’ve been gradually bringing the PrintABlok Printer to fruition. A combination of 3D Printing Professor’s PrintABloks project with the idea of Mini DVD Motor 3D Printers.

In 2021 I discovered the Recreator3D.com project and decided to give it a whirl. Soon combining PrintABloks into the Recreator3D’s MK6 Fun Size base to make my new core XY version. With encouragement from Josh at JRT3D.com and his Recreator3D project, I’m here today to share my progress.

On Display at SMRRF this year we had:

An attempt to Print A Blok from the PrintABloks Printer

Displaying the 3D Printing Professor’s PrintABloks

Displaying Pultruded filament from Plastic Bottles with the Recreator3D.com’s MK6 Fun Size unit.

We also had (hidden) a “Planktruder” with the Recreator3D MK5Kit Parts. Showing a basic concept of the pultruders design.

Displaying the Slunaz FF1R Filament Joiner - Great for joining PET1 filaments together.

Doug has big plans! He wants to turn the Recreator3D into a PrintABloks frame, making our pultrusion unit almost entirely 3D printable. With this setup, we can produce PET1 using the unit and make PET1 blocks with the PrintABloks printer. This means we’ll have two RepRap machines that can make filament, and that filament can be used to create more printers. Basically, we’re closing the loop by easily making our own filament from stuff in our recycling bins.

– Joshua R. Taylor of JRT3D.com

The SMRRF 2023 Table was Sponsored by:

Recreator3D.com

By Joshua R. Taylor of JRT3D.com

On Display:

MK6 Fun Size (our smallest unit allowing for space saving and time reduction)

MK5 Spooler “Planktruder” (a basic frame showing how basic you can use Recreartor3D’s pultrusion methods to keep the build basic and reduced in price while using what you have around your house)

Already 3D printers are fastly becoming items that are thrown away as freely as plastic bottles.

Not only does this unit help stop plastic waste, it also helps us look at our aging technology as new viable forms of functions. Thus giving a new life and purpose.

The Recreator 3D MK5Kit was made to be a universal solution for the use of most standard aluminum extrusions i3 style fdm printers.

With the over saturation of the market, the Ender 3 is one of the most used printers within the community. With it being the most affordable option as a 3D printer; most new users become discouraged, and easily send their slightly used printer back to Amazon.

These units are easier to be sold at a discount, then they are to be repaired and resold for very little profit. The printer becomes an inexpensive throw away or easily resold for a very low price if not given as a gift.

The Recreator 3D - Mk5Kit: Ender 3 is one of the cheapest options available for PET#1 pultrusion for 3D printing filament.

Its method of pultrusion is not a 100% solution to ending plastic waste, but is the easiest way to reclaim waste as usable filament.

For under $220 these units can be created by average people and turn homes into small recycling centers as well manufacturers among 3D printing.

Slunaz and the FF1r

By Stefano Lunazzi

URL: slunaz.com

On Display:

Slunaz FF1R: Better Than a New Spool

Coming from Europe; The SLUNAZ by Stefano Lunazzi, is currently running a now FULLY FUNDED Kickstarter campaign and plans to start shipping in February 2024.

An ideal solution for seamlessly combining a selection of filament materials. While it excels with PLA, ABS, PETG, and PET-B (commonly referred to as PET1; derived from DIY home Pultrusion methods, enabling the creation of customized 3D filament from plastic bottles)

The SLUNAZ FF1R is offered as a DIY small parts kit, which not only saves on shipping costs but also allows customers to 3D print the components themselves. This way, they can give their Slunaz FF1R a personal touch to match their style and other 3D printer accessories. ORDER YOURS NOW!

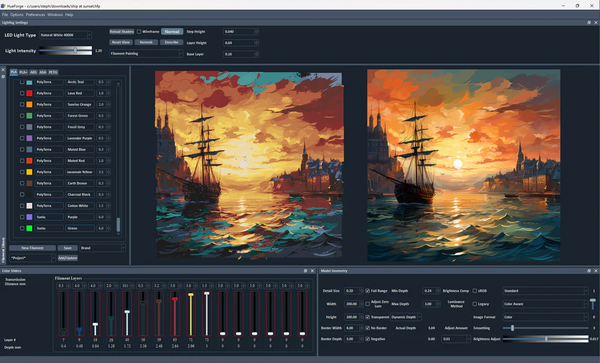

HueForge

By Steve Lavedas

URL: thehueforge.com

HueForge is software which allows you to create detailed multi-color 3D Prints using only Swap-by-Layer through a process we call Filament Painting.

HueForge isn’t a slicer or a painting program, HueForge generates a model file for you.

Then using the sliders you see on the bottom of the image, and the magic of Transmission Distance, predicts what your final print will look like after printing.

Many images have just 3-4 color swaps and can easily be managed by hand.

Baby Belt Pro

By Rob Mink at Printcepts

URL: printcepts.com

Rob has been an integral part of both Recreator3D.com, JRT3D.com as well helping Doug with his PrintABloks Printer’s configurations.

One of Doug’s 2024 goals is integrating Rob’s Baby Belt Design into his current design, making an automated variant.

The Baby Belt PRO:

The Baby Belt is the result of a year-long development effort to make the world’s most cost effective and reliable miniature toy belt printer.

Check it out on github

Auto Ejection Polar:

Our custom line of auto ejection printers. All open source and available for download over Thingiverse. The polar2 is a small and cheap entry to auto ejection, with off the shelf and 3d printed parts.

The Polar3 is the ‘pro’ version of the Polar series and has a 24” build disk.