SMRRF24: Bigger, and Better!

SMRRF24 was absolutely brilliant! I’ve been trying to think of a nice way to summarize the event this year, but honestly, I’m struggling because it was just so darn good. But wait, do we need to back up and cover what SMRRF is? Probably should.

What is SMRRF?

SMRRF stands for the Sanjay Mortimer RepRap Festival. It’s a fundraising event organized and run by The Sanjay Mortimer Foundation. This incredible charity helps neurodivergent youth get the support, guidance, and equipment they need to excel at what they do best. It’s a celebration of creativity, innovation, and community—and it’s impossible to leave without feeling inspired.

And you know what? I am so proud to say that I’ve been a Bronze Sponsor again for SMRRF! Supporting such a meaningful cause while diving into the world of 3D printing and DIY/Making culture? Sign me up every time.

Recreator3D

This was my second year hosting a table at SMRRF; this year again it was sponsored by Recreator3D.com.

Unlike last year, I have learned from prior experience. I had backup in the form of Karl: a BRILLIANT individual who’s part of the Recreator3D community. Karl had posted on LinkedIn about his Recreator3D MK5 build, and the timing couldn’t have been better. Myself and Josh reached out to Karl and asked if he wanted to come hang out and run the table - thankfully he agreed and the rest here is history. Karl did a superb job, and we already have plans for the next SMRRF for what we can improve.

Having Karl around was the best decision ever. Between the two of us, we managed to keep the energy high, answer the endless barrage of fantastic questions, and share the Recreator3D story with so many attendees.

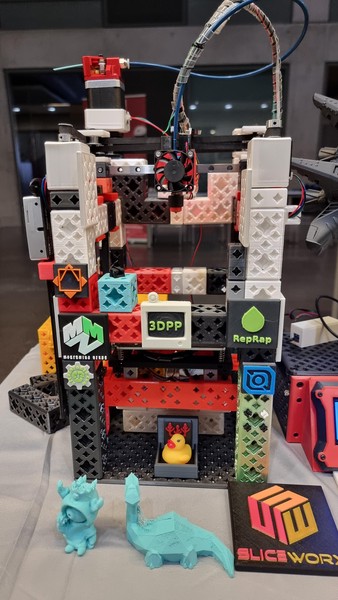

The PrintABlok Printers

The table was under the banner of Recreator3D, but my personal focus this year was on my PrintABlok Printers. This time, I had all three of them on display:

The Original DVD Linear Motor-Based Cartesian Build – This year, it was on display to better illustrate how far this 3D Printed 3D Printer project had come. Based on linear actuators from DVD drives with a theoretical build volume of 35mm cubed, it could have printed any of the GigantABlok or other parts needed for a functional model of the Mini-Sized CoreXY printer.

The Mini CoreXY Build – This year has been rife with improvements to this build. With assistance from Rob Mink of Printcepts, he helped push it further than ever by assisting with getting linear rails and pushing forward with switching to Nema11 motors instead of the 28BYJ48s. This was actively printing while on display, producing a few LowPolyDinos from the 3DPrintingProfessor’s collection. Also, some of us had fun seeing how fast we could get it to go before it started losing track of where it was. We got it to hit around 400mm/s of travel and 2000mm/s of accelleration. Which, for this 3d printed printer seems to be pretty fast!

The Big CoreXY Edition – Printed in filament provided by PolyMaker, this monster of cubic rainbow madness was GLORIOUS and an eye-catching masterpiece! I’m so happy that we were able to get this printer concepted, designed, and printed within a 4-month time span (thank you 3DJake for help getting the K1 we used to print this—it wouldn’t have happened otherwise).

This beauty took 8 kilos of filament and over 500 hours of printing, and it’s such a beautiful mashup of so many colors.

Some of the questions I kept getting asked were;

“Is this glued?” and “Are there any threaded rods inside the frame?”

The answer: No! No glue, no rods.

This printer was purely held together with the PrintABlok connectors unless unavoidable for mechanical parts, like the E3D Hemera XS hotend being screwed into the WhamBamSystems Mutant mobile plate.

Overall the PrintABlok Printers were incredibly well received - Lots of positive feedback from the visitors to SMRRF. I saw many faces that I’d seen the year before and they commented on how well the Mini CoreXY printer had come along, even had a few ask if there were plans for a kit (that would be cool).

It was brilliant being able to show off what could be done with PrintABlok from The 3D Printing Professor, and I am really looking forward to see what we can bring to the table next year.

Sponsors

I wanted to say thank you to the sponsors that have helped me better show off what I have accomplished this year.

Recreator3D - Josh over at Recreator3D has as ever been a brilliant sounding board and mentor for keeping the table on target making sure we deliver on best showing off what Recreator3D is all about with the Pultruder units and recycling at home.

Rob Mink — not only did he give his time and experience to help guide decision-making for using more suitable components for the project, but he also funded the rails, controller board, and some other parts for the PrintABlok Printers. Rob truly understood where I was roadblocked last year with the 28BYJs and 3mm rods because he had experienced similar challenges with the original BabyBelt build.

PolyMaker — thanks to the filament they provided, I was able to scale up the revised Mini CoreXY PrintABlok Printer to something closer to a standard size (Ender3 bed, 235x235mm). This allowed me to showcase more of their filaments and just have fun without worrying as much. I look forward to working with PolyMaker again in the future, further expanding into other fun projects!

WhamBamSystems — I posted a tweet about trying to create a modular PrintABlok tool head with a hotend that could connect via pogo pins. Peter from WhamBam saw it, reached out, and offered advice. After a 30-minute call, he provided one of their Mutant tool head systems, which made a huge difference to this project. It not only played into the modular nature of PrintABlok but also solved my tool head mounting issues in one fell swoop.

E3D — these guys are legends! They saw the printer last year at SMRRF23 in Oxford and somehow decided to entertain my request for the most overkill hotend/extruder combo I could think of. Enter the Hemera XS. As Rob might say (paraphrasing a car analogy I’m not fully equipped to understand), it’s like putting a V8 engine into a Reliant Robin—and I’m here for it.

3DJake — funnily enough, without their assistance in getting the Creality K1, the big printer wouldn’t have happened. They took a chance on my wild idea to inspire young makers at SMRRF, and I really hope we delivered. While we didn’t manage to hand out a bunch of TPU Chibimals (maybe next year), we showed what could be done by breaking a project into manageable pieces. That’s the heart of the PrintABlok Printers: breaking problems down into less intimidating steps and trusting the pieces will fit together eventually.

Returning Sponsors—SliceWorx, Alien3D, and Slunaz came back for another year of this madness, and I’m so glad they did. I enjoyed giving them project updates, and I think they appreciated seeing their SponsorBloks prominently displayed on the printer or table. Stefano from Slunaz—your FF1r filament joiner has been a game-changer for making use of pen/sample-sized filament pieces. It’s been a hit with the public and has been invaluable to this project.

I look forward to working with all of you again in the future.

Side Quests?

At SMRRF24 I found a little company called BlayzeTech, and they have a product called the RoboPad.

What is it?

It’s a little controller board that lets you build your own combat robot, think RobotWars! But it’s smaller, and not going to destroy your house (unless you really really try).

And of course I may have already integrated it into PrintABlok! Here is the Printables link for it: PrintABlok RoboPad build.